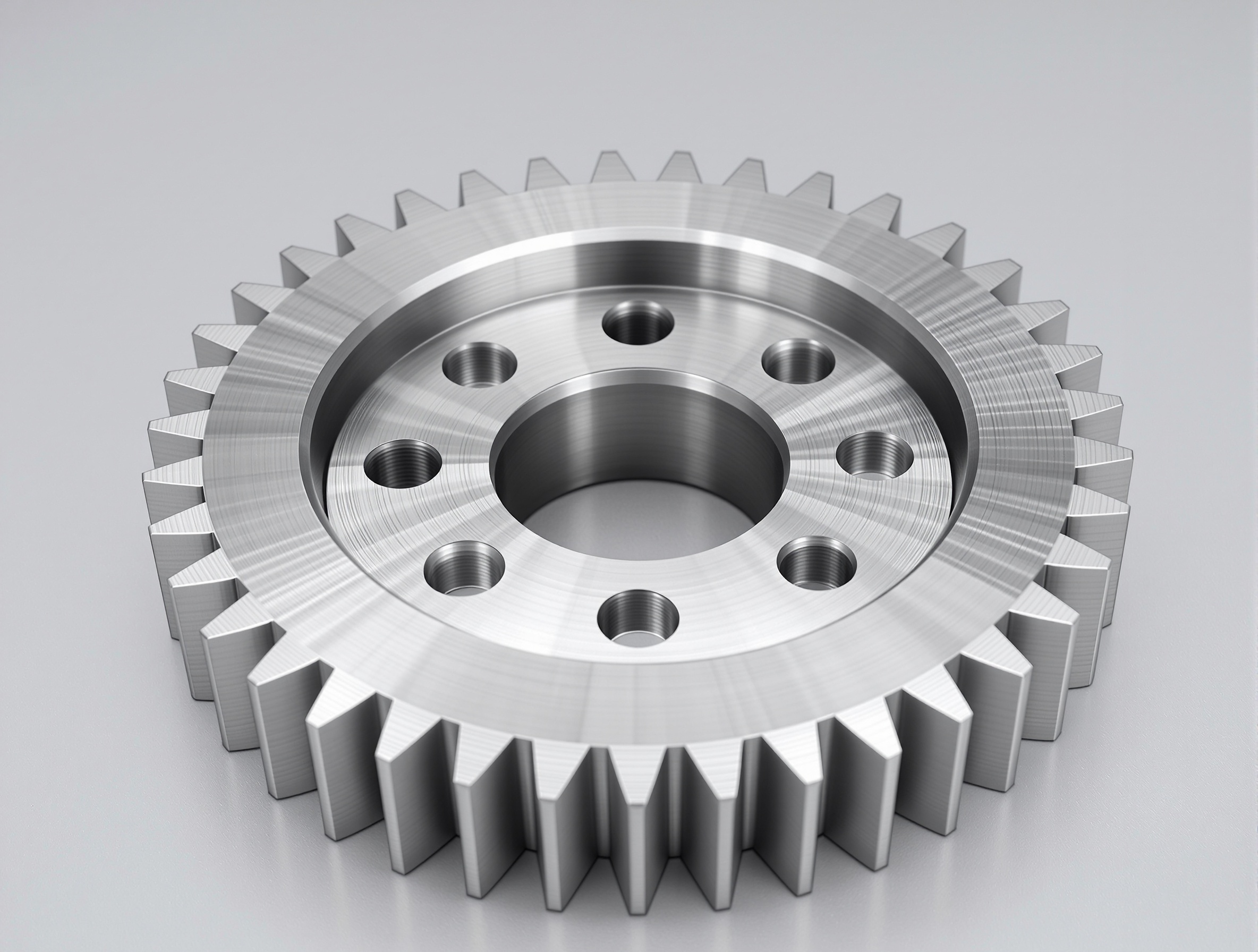

Transmission Parts

High-precision gears and shafts for automotive transmission systems

Project Overview

This transmission parts project showcases our expertise in manufacturing high-precision gears and shafts for automotive transmission systems. These components require exceptional accuracy in tooth geometry, surface finish, and heat treatment to ensure smooth operation and long service life.

Using advanced gear cutting technology and specialized heat treatment processes, we created components that deliver superior performance and reliability. Each part underwent rigorous inspection including gear tooth profile measurement, surface hardness testing, and noise vibration analysis to meet automotive industry standards.

Material

20CrMnTi Steel

Tolerance

DIN 6 Quality

Quantity

2,000 Units

Lead Time

5 Weeks

Technical Specifications

Precision engineering for optimal transmission performance

Gear Accuracy

DIN 6 quality grade precision

Surface Hardness

58-62 HRC case hardness

Low Noise

Optimized tooth profile for quiet operation

Long Life

Designed for 200,000+ km service life

Manufacturing Process

Advanced gear manufacturing technology

Gear Cutting

- Hobbing process

- Shaping & shaving

- Grinding finish

- Profile inspection

Heat Treatment

- Carburizing

- Quenching

- Tempering

- Case hardening

Quality Control

- Gear tooth inspection

- Hardness testing

- Noise testing

- Dimensional check

Related Projects

Explore more automotive and precision manufacturing projects

Need Precision Transmission Parts?

Let's create high-quality gears and shafts for your automotive applications