RF Waveguide

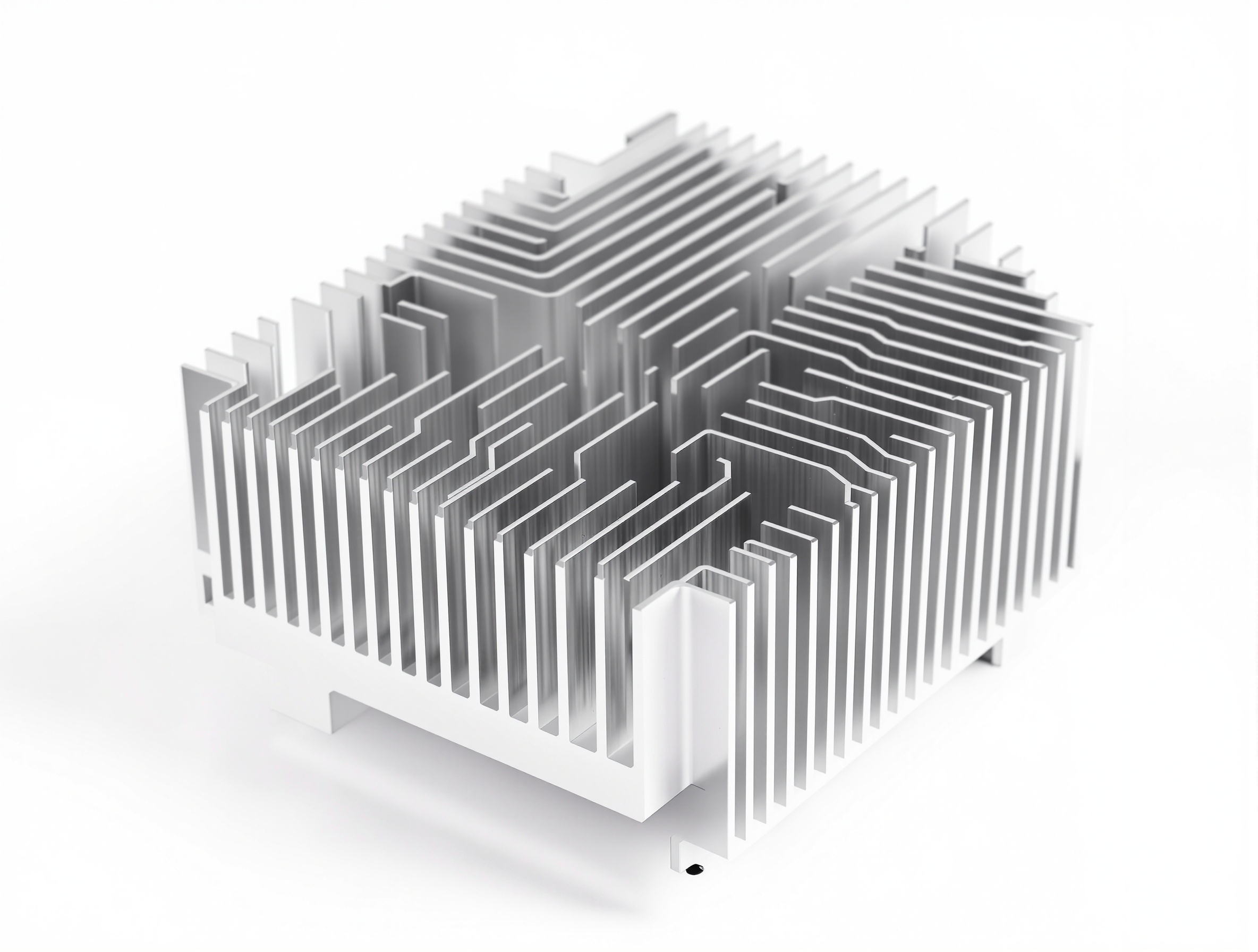

Precision aluminum waveguide components for high-frequency RF applications

Project Overview

This RF waveguide project required manufacturing precision aluminum components for high-frequency telecommunications equipment. The waveguides needed extremely tight tolerances and superior surface finish to minimize signal loss and ensure optimal RF performance.

Using advanced CNC milling and EDM processes, we achieved the precise internal dimensions and smooth surfaces critical for waveguide performance. Gold plating was applied to all internal surfaces to maximize conductivity and minimize insertion loss across the operating frequency range.

Material

Aluminum 6061-T6

Tolerance

±0.0003"

Quantity

800 Units

Lead Time

5 Weeks

Technical Specifications

Detailed specifications and capabilities demonstrated in this project

RF Performance

- Frequency range: 8-12 GHz

- Insertion loss: <0.1 dB

- VSWR: <1.15:1

- Power handling: 10 kW

Manufacturing Process

- CNC milling

- Wire EDM

- Gold plating

- Precision assembly

Quality Standards

- Network analyzer testing

- Dimensional inspection

- Surface roughness: Ra 0.4μm

- Plating thickness verification

Manufacturing Process

From raw material to finished component - our comprehensive manufacturing workflow

Material Preparation

CNC Milling

Gold Plating

RF Testing

Related Projects

Explore more precision electronics manufacturing projects

Ready to Start Your Project?

Let's discuss how we can bring your RF components to life with precision and quality