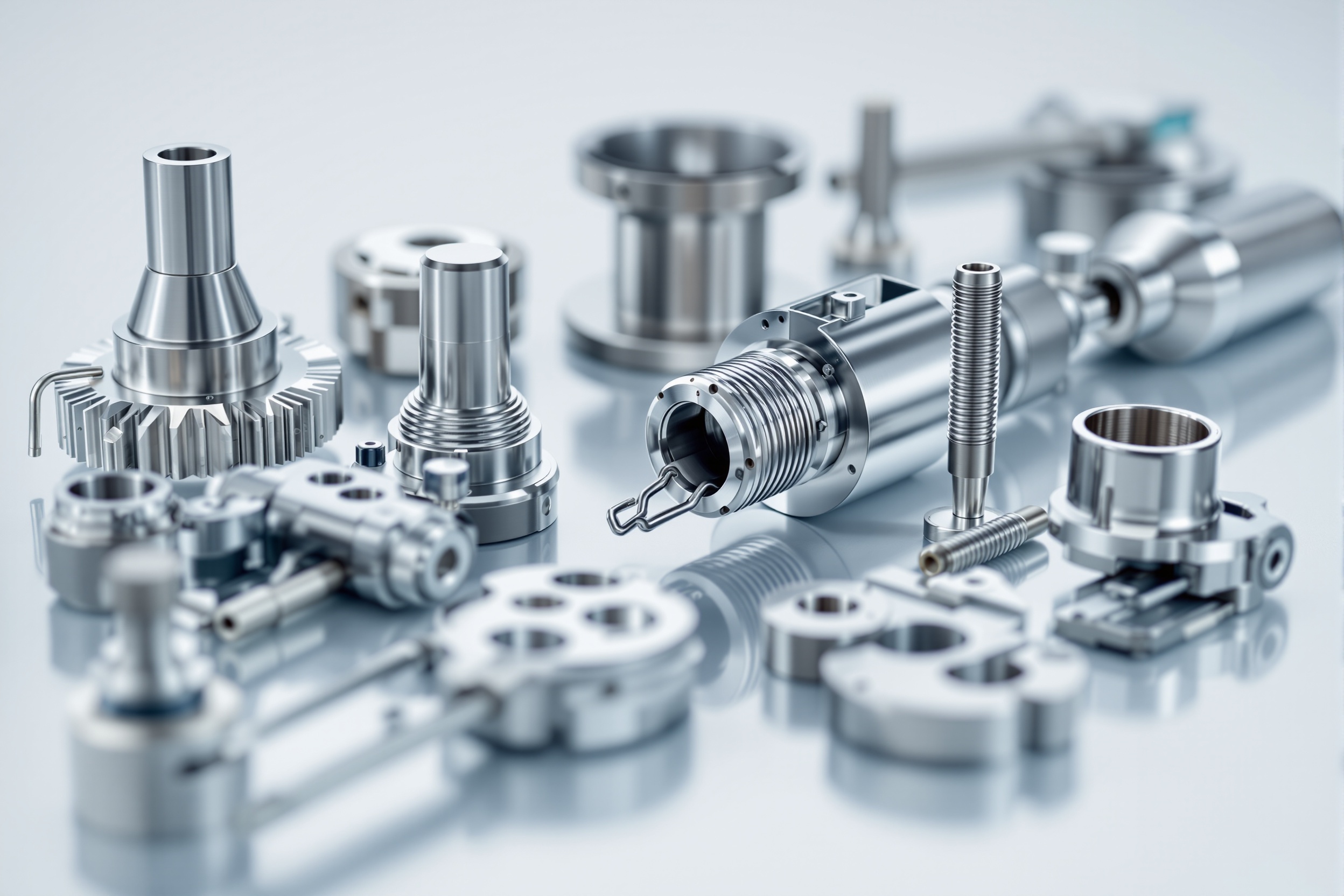

Swiss CNC Machining

Ultra-precision Swiss-type turning for small, complex parts with exceptional accuracy and surface finish. Our sliding headstock lathes deliver unmatched precision for medical, aerospace, and electronics components.

Swiss Turning Capabilities

Our Swiss-type CNC machines combine precision turning with live tooling for complete part manufacturing in a single operation.

Ultra-Precision Turning

Sliding headstock design provides superior support for long, slender parts with exceptional accuracy.

Live Tooling

Integrated milling, drilling, and cross-drilling capabilities for complete parts in one operation.

High-Speed Production

Optimized for high-volume production of small, complex components with consistent quality.

Micro Precision

Tolerances as tight as ±0.0002" for critical dimensions

Guide Bushing Support

Eliminates deflection for long, slender workpieces

Complete Parts

Multiple operations in single setup reduce handling

High Volume Ready

Optimized for production runs of thousands of parts

Materials We Process

We machine a comprehensive range of materials optimized for Swiss-type turning applications.

Industry Applications

Our Swiss CNC machining serves industries requiring the highest precision for small, complex components.

Medical Components

Bone screws, dental implants, surgical instruments, and catheter components with biocompatible materials.

Electronics Connectors

Precision connector pins, contact probes, and miniature shafts for electronic assemblies.

Aerospace Fasteners

High-strength fasteners, actuator components, and sensor housings for aviation applications.

Frequently Asked Questions

Common questions about Swiss CNC machining

Need Precision Swiss Machining?

Upload your technical drawings and receive a detailed quote within hours. Our experienced team is ready to help with your Swiss-type turning project.