Surgical Robot Arms

Precision components for robotic surgical systems with exceptional accuracy

Project Overview

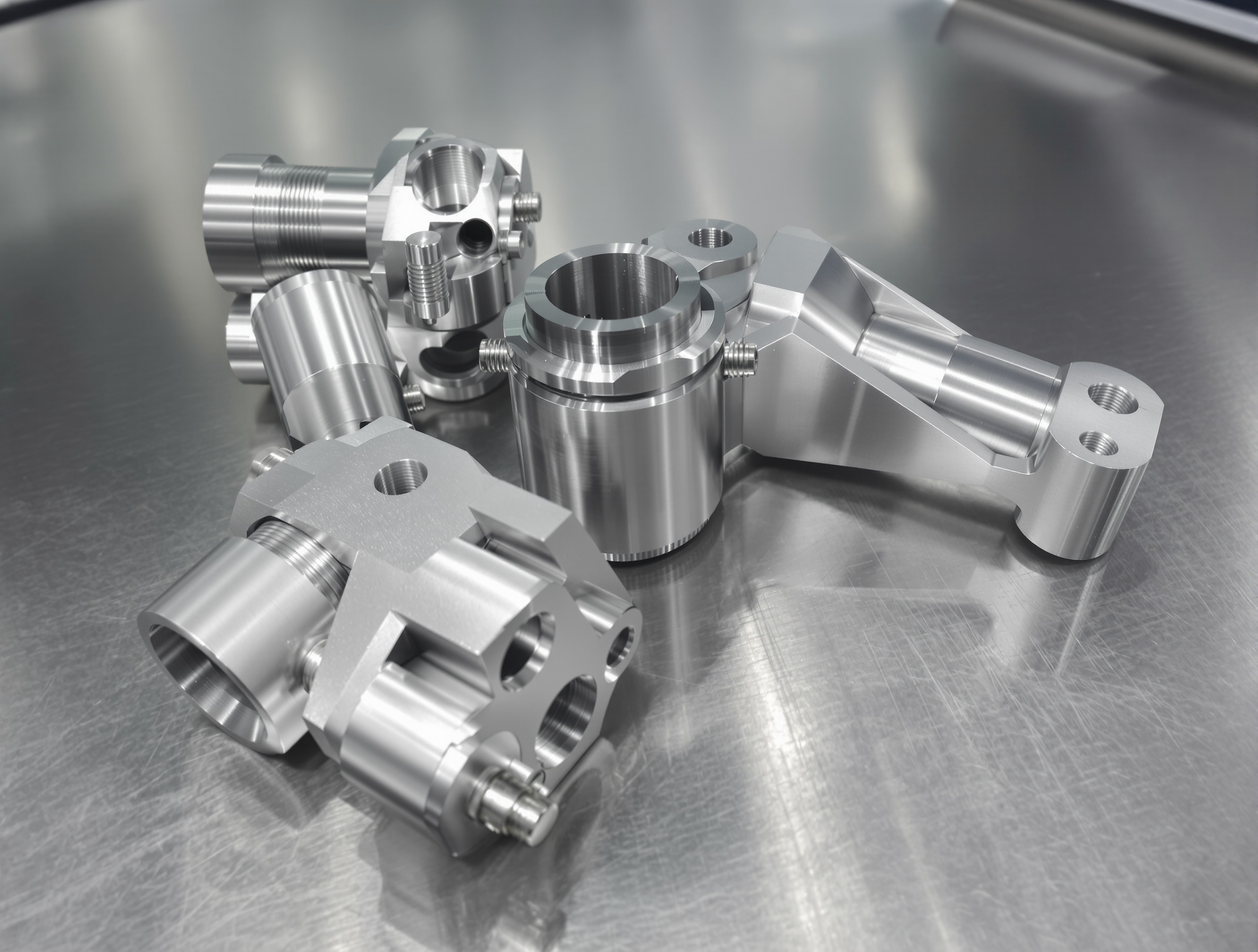

This project involved manufacturing precision components for next-generation surgical robotic systems. The parts required ultra-tight tolerances, biocompatible materials, and exceptional surface quality to enable precise surgical movements and ensure patient safety.

Our team utilized advanced 5-axis CNC machining and Swiss turning to create complex joint assemblies with minimal backlash and smooth articulation. Every component was manufactured in our ISO 13485 certified facility and underwent rigorous inspection to meet medical device standards.

Material

316L Stainless Steel

Tolerance

±0.0002"

Quantity

400 Sets

Lead Time

8 Weeks

Technical Specifications

Detailed specifications and capabilities demonstrated in this project

Precision Engineering

- 5-axis CNC machining

- Tolerance: ±0.0002"

- Surface finish: Ra 0.4μm

- Backlash: <0.001"

Medical Compliance

- ISO 13485 certified

- FDA registered facility

- Biocompatible materials

- Clean room assembly

Quality Control

- CMM inspection

- Functional testing

- Material traceability

- Passivation treatment

Manufacturing Process

From raw material to finished component - our comprehensive manufacturing workflow

Material Inspection

5-Axis Machining

Clean Room Assembly

Functional Testing

Related Projects

Explore more medical and precision manufacturing projects

Ready to Start Your Project?

Let's discuss how we can bring your medical device components to life with precision and quality