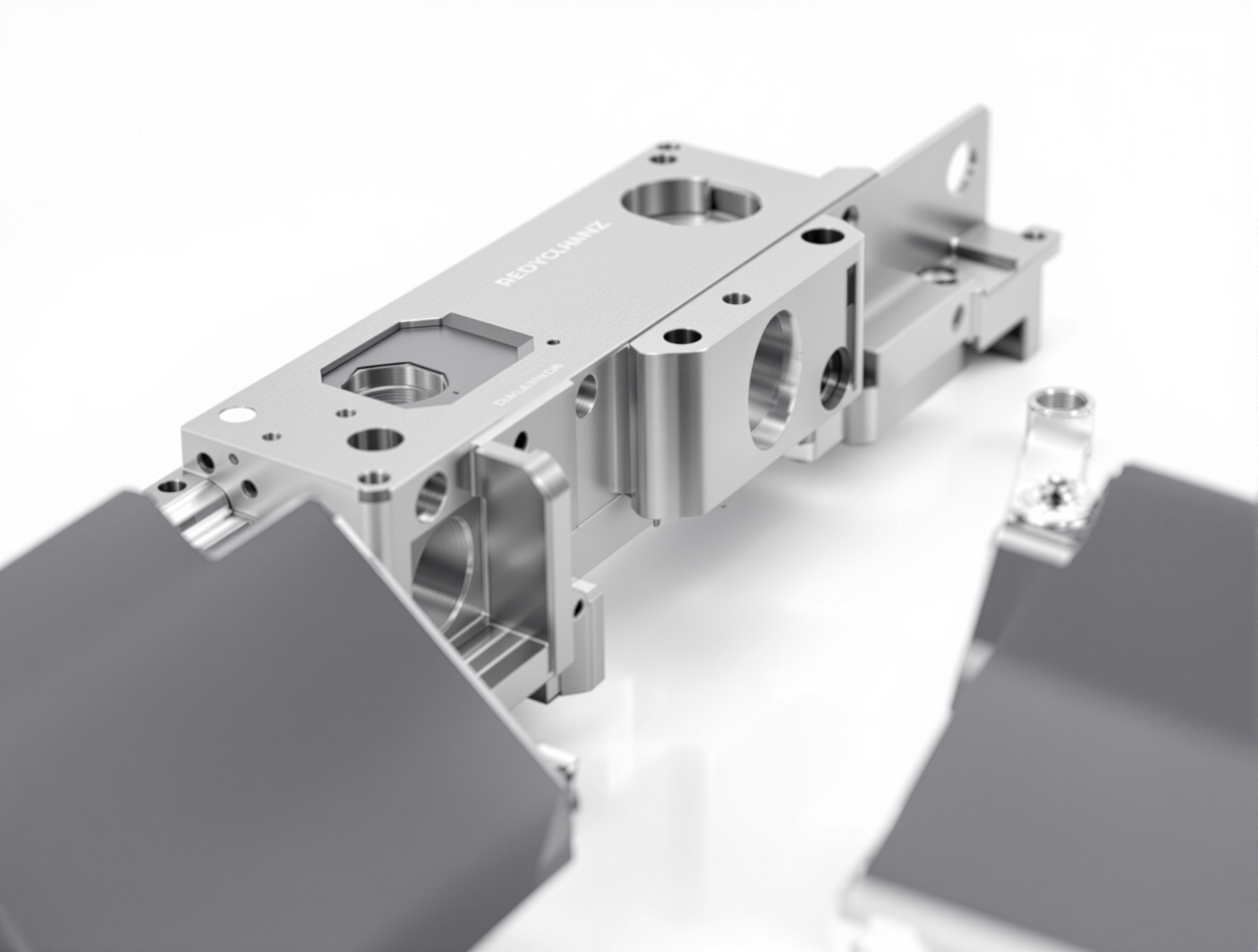

Aerospace Component

Precision machined titanium parts for aircraft systems with exceptional quality and reliability

Project Overview

This aerospace component project showcases our expertise in machining high-performance titanium parts for critical aircraft systems. The component required exceptional precision, tight tolerances, and rigorous quality control to meet aerospace industry standards.

Our team utilized advanced 5-axis CNC machining technology to achieve the complex geometries and surface finishes required for this demanding application. Every part underwent comprehensive inspection and testing to ensure compliance with AS9100 aerospace quality standards.

Material

Titanium Ti-6Al-4V

Tolerance

±0.0005"

Quantity

500 Units

Lead Time

3 Weeks

Technical Specifications

Detailed specifications and capabilities demonstrated in this project

Precision Machining

- 5-axis CNC milling

- Tolerance: ±0.0005"

- Surface finish: Ra 0.8μm

- Complex geometries

Quality Control

- AS9100 certified

- CMM inspection

- Material certification

- Full traceability

Manufacturing Process

- CAD/CAM programming

- Advanced tooling

- Climate-controlled facility

- Clean room assembly

Manufacturing Process

From raw material to finished component - our comprehensive manufacturing workflow

Material Preparation

CNC Machining

Quality Inspection

Final Assembly

Related Projects

Explore more aerospace precision manufacturing projects

Ready to Start Your Project?

Let's discuss how we can bring your aerospace components to life with precision and quality